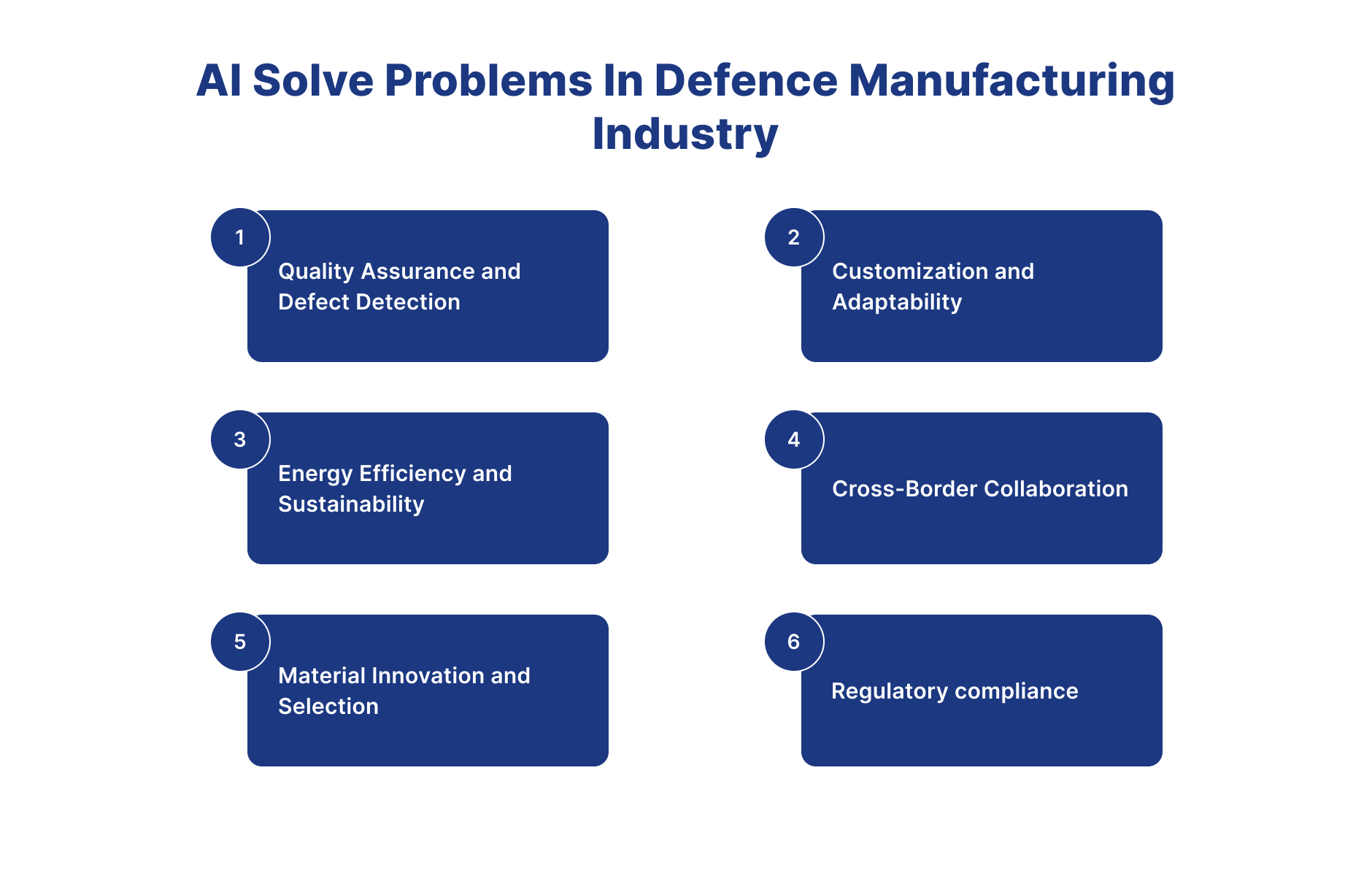

AI Solve Problems In Defence Manufacturing:6 problems that can be solved using AI in defence manufacturing To Revolutionize It.

the emergence of AI Solve Problems In Defence Manufacturing and revolutionized defence production processes.

Introduction

- In the defence industry, being ahead of the curve is critical to ensuring nations' safety and security. This complex business, however, faces various challenges that can hinder efficiency, quality control, and overall effectiveness. Fortunately, the emergence of AI Solve Problems In Defence Manufacturing and revolutionized defence production processes. AI solutions are transforming the defense landscape from predictive maintenance and automated defect detection to intelligent supply chain management and enhanced cybersecurity. As technology advances, the integration of AI will undoubtedly continue to reshape the industry, leading to a more agile, efficient, and resilient defence sector.

- AI has developed as a strong technology capable of analysing massive volumes of data, learning from patterns, and making sound conclusions. It enables capabilities such as predictive maintenance, quality control, supply chain optimisation, and sophisticated robotics previously thought to be unachievable or inefficient. Defence manufacturers may now solve crucial difficulties more efficiently, boost productivity, and improve the overall quality and dependability of defense equipment by embracing AI technology.

AI Solve Problems In Defence Manufacturing Industry

1.Quality Assurance and Defect Detection:

-

Quality assurance was a crucial problem in the conventional environment of defence manufacturing. Human-operated inspection techniques, while necessary, were constrained by intrinsic human limitations. Detecting minute flaws or irregularities in complicated defence components demanded considerable attention, and even the most experienced human inspectors struggled to maintain consistent perfection. The manual nature of these checks added unpredictability, making it impossible to assure consistent quality throughout the manufacturing process.

-

AI-driven autonomous manufacturing methods transform defence production by incorporating robotic systems directed by sophisticated algorithms. These systems perform complicated production processes with unmatched precision, speed, and adaptability. As a result, the manufacturing environment is marked by efficiency, accuracy, and the capacity to respond quickly to changing production requirements. In this way AI Solve Problems In Defence Manufacturing industry.

2.Customization and Adaptability:

-

Customisation in defence production is critical owing to the various nature of defence equipment and the diverse demands of different defence situations. Traditional manufacturing lines, designed for bulk production, struggled to effectively pivot to meet specialized requirements or adjust to rapid shifts in defence priorities. The time and effort necessary to reorganize manufacturing processes and execute changes hampered the industry's ability to adapt to changing needs quickly.

-

AI-driven customization enables adaptive manufacturing processes. Machine learning algorithms optimize real-time production settings, allowing quick responses to changing demands. This adaptability is critical for meeting changing defence needs since it ensures that production processes may be modified to meet particular and growing demands. In this way AI Solve Problems In Defence Manufacturing industry.

3.Energy Efficiency and Sustainability:

-

Energy efficiency and sustainability were frequently ignored in the old defence industrial scenario. While traditional manufacturing procedures effectively produced defence equipment, they lacked a significant focus on optimising energy use and minimising environmental impact. This disregard for sustainability sparked worries about resource inefficiency, rising carbon footprints, and the ecological consequences of energy-intensive production.

-

AI is crucial in reducing energy usage and boosting sustainability in defence production. Machine learning algorithms analyse energy use trends to discover areas for improvement. This decreases environmental impact and saves money, as a consequence of which the manufacturing process is more sustainable and cost-effective. In this way, AI solve the Problems In the Defence Manufacturing industry.

4.Cross-Border Collaboration:

-

Geopolitical factors, legal disparities, and worries about securing sensitive information all posed challenges to establishing powerful collaborative networks. National security objectives occasionally conflicted with the requirement for open information exchange, making it difficult to effectively address common issues, including rising threats, technological breakthroughs, and global security difficulties.

-

AI-powered communication and collaboration solutions enable global defence manufacturers to share real-time information. Real-time data analysis and insights promote international collaboration by allowing for a collective response to everyday difficulties and guaranteeing a unified front in tackling global security concerns. In this way AI Solve Problems In Defence Manufacturing industry.

5.Material Innovation and Selection:

-

Before the incorporation of AI, material innovation and selection faced obstacles stemming from the complexity of available materials, increasing technical breakthroughs, and the necessity for comprehensive optimisation. While human expertise is immense, it may be restricted in analysing large datasets of material attributes and forecasting their performance under various scenarios. Because of this constraint, possible oversights and poor material selections occurred, affecting the overall efficacy and lifetime of defence equipment.

-

AI analyses massive materials databases, considering aspects like strength, weight, and cost-effectiveness. Machine learning algorithms forecast material performance under various scenarios, assisting in selecting ideal materials for defence manufacture. This guarantees that the finished goods fulfill high-performance standards. In this way AI Solve Problems In Defence Manufacturing industry.

6.regulatory compliance:

-

Before the widespread use of AI, defence manufacturers had the daunting burden of keeping up with ever-changing rules and ensuring that their processes adhered to the most recent requirements. Compliance management was a time-consuming and resource-intensive endeavor that involved analyzing complicated regulatory frameworks, monitoring developments, and implementing adjustments as needed.

-

AI aids in regulatory landscape navigation by continually monitoring and understanding regulatory developments. AI-powered automated compliance management solutions guarantee that defence production processes are current, lowering the risk of noncompliance and the accompanying fines. In this way AI Solve Problems In Defence Manufacturing industry.

Conclusion

- In conclusion, using AI in defence production answers complicated challenges while revolutionising the industry's capacities and efficacy. AI has significantly improved processes such as quality control, predictive maintenance, supply chain optimisation, advanced robotics, cybersecurity, sensor data analysis, autonomous vehicles and drones, and simulation and training by leveraging machine learning, computer vision, and advanced data analytics.

How Digiqt will help you to adapt AI in your company

-

At Digiqt, we are dedicated to assisting companies in automating critical processes. Our highly skilled and professional team ensures the timely development and delivery of AI software. We commence by thoroughly understanding our client's specific requirements, and based on these requirements, our proficient team develops the AI software. Furthermore, we provide our clients monthly updates on the software development progress.

-

Digiqt's commitment to automation, client-centric software development, and regular updates ensures efficiency and effectiveness in streamlining insurance operations.

Contact Us

Frequently Asked Questions

What are AI Solve Problems In Defence Manufacturing?

AI Solve Problems In Defence Manufacturing are AI-powered systems that automate and optimize processes using machine learning, natural language processing, and intelligent decision-making capabilities.

How do AI Solve Problems In Defence Manufacturing work?

AI Solve Problems In Defence Manufacturing work by analyzing data, learning patterns, and executing tasks autonomously while integrating with existing systems to streamline operations and improve efficiency.

What are the benefits of using AI Solve Problems In Defence Manufacturing?

The benefits include increased efficiency, reduced operational costs, improved accuracy, 24/7 availability, better customer experience, and data-driven insights for decision-making.