AI In Vehicle Manufacturing: 7 Ways How AI Is Transforming Vehicle Manufacturing In the Automobile Industry

The use of AI In the Automobile Industry has ushered in a new age of innovation, safety, and efficiency.

Introduction

- As the automobile industry races toward an innovative future, one technological factor stands out as a transformative force: artificial intelligence (AI). The use of AI In Vehicle Manufacturing processes is more than a step forward; it is a paradigm change. In this blog, we will investigate the tremendous influence of AI on every step of automotive production, from the initial spark of creative inspiration to the final touchpoints of consumer connection. Using a before-and-after bridge content strategy approach, we dig into how AI is altering the core of how automobiles are imagined, manufactured, and experienced.

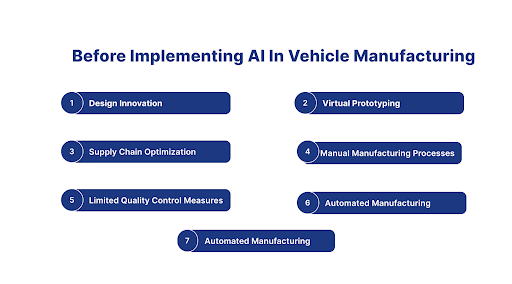

Before Implementing AI In Vehicle Manufacturing

1.Design Innovation

- Before the advent of AI, automotive design was a rigorous manual process that relied primarily on the skill and intuition of human designers. The design team, equipped with sketches and actual models, confronted transforming innovative notions into viable, market-ready cars. The lack of data-driven insights frequently resulted in a time-consuming trial-and-error method in which designers relied on their expertise to judge consumer preferences.

2.Virtual Prototyping

- Traditional prototyping entailed fabricating physical models to evaluate design concepts and their practicality. This analog process costs tremendous time and resources, frequently causing delays in the manufacturing plant. The inability to quickly explore various design iterations hampered the creative exploration of alternate concepts. As a result, the sector faced lengthier development cycles and higher prototyping costs.

3.Supply Chain Optimization

- Before AI involvement, supply chain management relied on historical data and periodic demand estimates. While this technique was well-established, it lacked the agility to adjust to rapid market swings or unexpected disruptions. Inventory levels proved difficult to optimize, resulting in overstocking or shortages. The lack of real-time insights hampered the capacity to handle supply chain concerns proactively, resulting in a less responsive and efficient system.

4.Manual Manufacturing Processes

- Car assembly lines were distinguished by manual labor and human-operated machinery. While human talent and craftsmanship were essential to the manufacturing process, the reliance on manual labor brought issues such as discrepancies in product quality and production speed constraints. The human factor limited efficiency increases, affecting the entire output of the industrial operation.

5.Limited Quality Control Measures

- Before AI, quality control depended mostly on human inspectors physically inspecting produced automobiles. This strategy, while effective to some extent, was prone to supervision and subjective assessment. Identifying small faults or possible concerns in the early manufacturing phases proved difficult, resulting in more recalls and post-production quality issues.

6.Automated Manufacturing

- The symphony of AI-driven robots and automation in industrial plants alters the assembly line story. Robots directed by powerful AI algorithms accomplish difficult jobs with unrivaled precision, resulting in increased production speeds and considerably reduced mistakes. The result is a seamless marriage of human skill and mechanical efficiency.

7.Quality Control

- The watchful eye of AI extends to quality control, converting it from a human inspection procedure to an automated, data-driven undertaking. AI-powered computer vision systems methodically search for flaws, ensuring that only vehicles that satisfy high-quality requirements move along the production line. This combination of AI and quality control represents a paradigm change in industrial excellence.

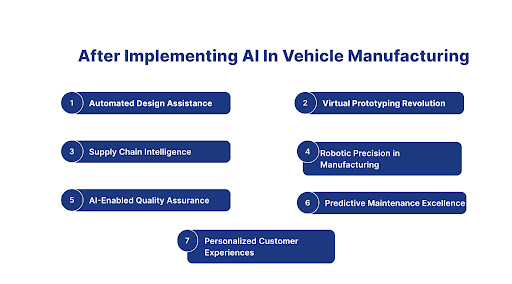

After Implementing AI In Vehicle Manufacturing

1.Automated Design Assistance

- Design innovation takes on a new level with the use of AI. AI algorithms evaluate massive information, such as customer preferences, market trends, and historical design data. Designers now use AI technologies that provide ideas and insights, speeding up brainstorming. AI-driven design helps enable quick exploration of design alternatives, ensuring that the final product closely corresponds with both creative aspirations and commercial expectations.

2.Virtual Prototyping Revolution

- AI In Vehicle Manufacturing converts virtual prototyping into a dynamic and iterative process. Advanced simulation algorithms can forecast how design modifications may affect the vehicle's performance, safety, and aesthetics. This degree of precision lowers the need for prototypes, saving time and money. Designers may now experiment with several iterations in a virtual world, enabling a more flexible and adaptive approach to product creation.

3.Supply Chain Intelligence

- AI In Vehicle Manufacturing adds a new degree of intelligence to supply chain management. Predictive analytics driven by AI evaluates real-time data, market trends, and external factors, allowing producers to forecast demand variations and manage inventory levels. The supply chain becomes more responsive and adaptable, with AI algorithms recommending the best buying techniques. This reduces the danger of shortages or surplus inventory and leads to cost savings across the supply chain.

4.Robotic Precision in Manufacturing

- AI In Vehicle Manufacturing is revolutionizing the industrial process. Robots armed with AI algorithms can accomplish complex jobs with unrivalled precision. They operate in tandem with human workers to increase efficiency and production. Developing collaborating robots, or cobots, allows for a safer and more flexible industrial environment. Consequently, manufacturing speed, consistency, and overall product quality have all increased significantly.

5.AI-Enabled Quality Assurance

- With the use of AI In Vehicle Manufacturing, quality control experiences a paradigm change. AI-powered computer vision systems check every part of the car during and after construction. The systems can more accurately discover flaws, inconsistencies, and possible faults than humans. This guarantees that only vehicles that satisfy high-quality requirements move along the assembly line, considerably minimizing the possibility of post-production difficulties.

6.Predictive Maintenance Excellence

- Post-production, AI In Vehicle Manufacturing continues to improve the user experience through predictive maintenance. Algorithms examine real-time data from sensors within the car to forecast when components are likely to break. This proactive approach to maintenance not only enhances vehicle durability but also minimizes the chance of unexpected failures. As a result, client happiness and brand loyalty are higher.

7.Personalized Customer Experiences

- AI In Vehicle Manufacturing is expanding its reach into the area of consumer experience. Vehicles featuring AI-driven technologies, such as voice recognition, individualized infotainment systems, and sophisticated driver assistance, provide a bespoke and intuitive driving experience. The automobile transforms into a connected, intelligent friend, adjusting to the driver's preferences and ensuring a smooth and comfortable ride.

Conclusion

- The influence of AI on vehicle manufacturing emerges as a symphony of creativity as we negotiate the domains of design, production, and post-production. The before-and-after bridge content strategy framework reveals an evolutionary story in which AI complements and leads the automobile industry toward an age marked by efficiency, innovation, and outstanding consumer experiences. As we look ahead, it's evident that the impact of AI In Vehicle Manufacturing is more than simply a technological update; it's a deep redefining of what's possible in the world of automobiles.

How Digiqt will help you adapt AI in your company

-

At Digiqt, we are dedicated to assisting companies in automating critical processes. Our highly skilled and professional team ensures the timely development and delivery of AI software. We commence by thoroughly understanding our client's specific requirements, and based on these requirements, our proficient team develops the AI software. Furthermore, we provide our clients with monthly updates on the software development progress.

-

Digiqt's commitment to automation, client-centric software development, and regular updates ensures efficiency and effectiveness in streamlining insurance operations.

Contact Us

Frequently Asked Questions

What are AI In Vehicle Manufacturing?

AI In Vehicle Manufacturing are AI-powered systems that automate and optimize processes using machine learning, natural language processing, and intelligent decision-making capabilities.

How do AI In Vehicle Manufacturing work?

AI In Vehicle Manufacturing work by analyzing data, learning patterns, and executing tasks autonomously while integrating with existing systems to streamline operations and improve efficiency.

What are the benefits of using AI In Vehicle Manufacturing?

The benefits include increased efficiency, reduced operational costs, improved accuracy, 24/7 availability, better customer experience, and data-driven insights for decision-making.